- In house design, drafting and 3D modelling using state of the art Autocad Inventor.

- Acceptance of customer files and data in its native format.

- Design from concept to manufacture of the finished part.

- Cam programming from models and drawing using Inventorcam.

Our CNC machines turn 280mm diameter by 450mm between centres. Automatic CNC turning machines with sub spindle, cross drilling and milling up to 65mm bar diameter with magazine bar feeds.

CNC Sliding Head Machines from 1/16" to 32mm diameter with sub spindle, cross drilling and milling with magazine bar feeds.

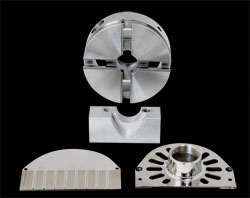

CNC Machining Centres four axes: Capacity 510 x 762 x 435mm

Full inspection facilities with quality control accreditations to ISO 9001:2008.

Lathes

Doosan Puma 2600Y

The new Puma 2600 lathe provides increased accuracy, repeatability, performance and process reliability. The machine has a 12" chuck with bar capacity of 76.2mm or up to 376mm from billet. With a bed length of 760mm has the capability to turn 500mm between centres with face and cross milling/drilling on the Y axis.

3 x 2 Axis CNC Turning Centres with Fanuc controls having a machining envelope of up to 250mm Ø x 400mm in length and the capability to produce components from bar to a max diameter of 65mm (stock Ø) or 150mm from billets

Milling

3 x 3 Axis CNC milling machines with Siemens and Fanuc controls having a machining envelope of up to 510mm x 435mm x 732mm (XYZ) with the additional 4th Axis capabilities available.

New Sliding Head

4 x CNC Sliding Head machines with sub spindle, driven tooling, bar feed; has up to Ø32 bar capacity and component length to 500mm. Up to 5 Axis machining, of small complex parts with the ability to work “Lights out”.

Nakamura

2 x CNC Multi Axis, twin spindle, twin turret machining centres with Fanuc control have the ability to produce one hit complex components from up to Ø65 bar capacity; having up to 7 axis and full driven tooling capabilities. Again with the ability to work “Lights out”.

Welding

MIG & TIG welding facilities.

Manual Machining

1x Bridgeport Milling Machine

1x Colchester Triumph Centre Lathe with gap. 500mm swing x 600mm between centre's.

1x Jones and Shipman 510 surface grinder 18"x8"